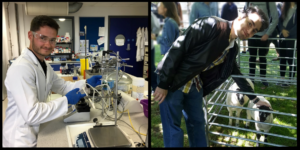

Authors: Moein Mir Fakhar and Scott Allan -

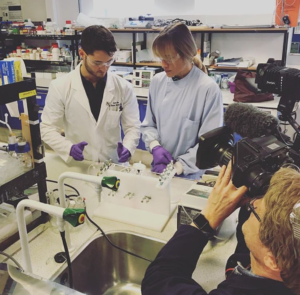

Within Dr Marianne Ellis’ Tissue Engineering Group in the Department of Chemical Engineering researchers are designing bioreactors to scale-up cultured meat production. Two of the PhD students, we like to call ourselves Moein and Scott, want to tell you about cultured meat and the work we are doing in the lab (before the pandemic at least) to contribute to the future of food.

Cultured meat is produced by growing stem cells taken from an animal biopsy, within a bioreactor outside of the animal. This sounds like one of those mad ideas in a bad science-fiction movie, right? We almost agree with you, apart from the fact that it’s actually a good science-fiction movie, because to paraphrase Winston Churchill, why grow a whole chicken if you can just grow a breast or a wing?

We believe we need cultured meat for many reasons, the advantages are endless! It has the potential to contribute to our global goals of addressing food security as well as climate change. A future cultured meat process is expected to need at least 95% less fresh water and arable land compared to rearing livestock and is not restricted by localised climates.

For those who are not very familiar with the field, this is no-longer science fiction, it has already been proven possible by the first lab grown burger in 2013, along with other edible meat products like sausages, meatballs and even shrimp dumplings. The problem is that the first burger cost around $300,000! Currently none of these products are available commercially and so you can’t pop to the shops for cultured meat just yet. To reach this point we need to scale up production to bring down the costs. Additionally, it was not textured meat like a full-cut steak; this presents further technical challenges that need to be addressed.

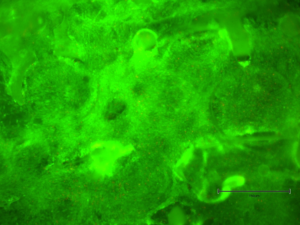

We are working on two different types of high cell density bioreactors; Scott aims to grow and increase the number of muscle cells in hollow fibre bioreactors, while Moein aims to take these cells and make real 3D textured meat like steaks rather than processed meat. High cell density bioreactors can be many times smaller than conventional reactors. The smaller volume helps to cut a big chunk of capital and operational costs. To do this, perfusion bioreactors aim to synthetically replicate the natural capillary system in muscles to efficiently provide nutrients to the cells. For Moein, this means to fabricate 100,000 hair-thin channels in a space as small as 1 cm3 (It will be less for practical reasons; but that number still shows your capillaries distribution)! Not a big deal at all! This is called microfabrication; and it is actually common as we use it in our smart phones and laptops. However, our challenge is to make it as cheap as possible; for our final product is meat and you don’t want to pay the price of a laptop for your every meal! Or, do you?!

Respond