Author: Dr Matthew Cole -

The past ten months in the Department of Electronic & Electrical Engineering have been busy, perhaps none more so than in the group I lead, the new Nano Vacuum Electronics Group. We focus on the integration of nanomaterials to produce next-generation electronics for advanced healthcare.

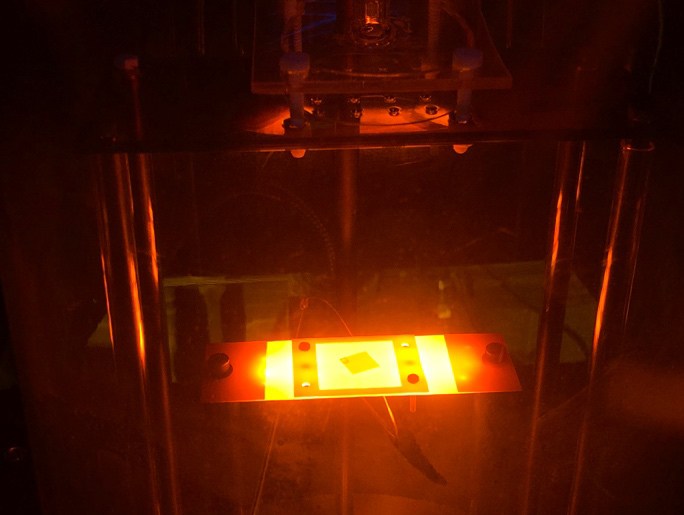

We have recently demonstrated new nanomaterial manufacturing capacities that go a long way in bolstering the University’s already established role within the nanotechnology research field. Central to the Group's new capacity are the two new Aixtron Black Magic Chemical Vapour Deposition (CVD) reactors. Capable of high temperature, rapid through put processing, these reactors have allowed the group to grow aligned carbon nanotubes and high-quality graphene at the University for the first time.

Working closely with industry, we have demonstrated the ability to produce vertical and horizontal carbon nanotubes offering a new paradigm in ultra-precise engineering that is truly at the atomic scale. Built atom-by-atom, these nanomaterials underpin a huge range of new technologies that will likely find application across multiple industries in the coming years. It is hoped that the CVD reactors will, in the coming year, allow for the growth of other two-dimensional materials that have not yet been produced elsewhere.

Our final-year undergraduate students have helped us with the development and subsequent inkjet printing, via a modified printer, of silver nano inks and graphene inks; both significant breakthroughs towards the production of low-cost disposable electronics. We've manufactured the University of Bath logo on substrates and commercial grade paper using different materials like graphene ink and nanotubes.