Author: Dr Rob Wortham -

Last month, our second cohort of MSc students studying Robotics and Autonomous Systems completed their first in-lab assessment – the Robot Arm Challenge. They were accompanied by several ART-AI students taking the Robotic Platform Engineering unit as part of their first year programme. The Robot Arm Challenge is inspired by the frequent need to move hazardous materials between processing stages using autonomous machines, particularly by the processing and handling of nuclear fuel rods.

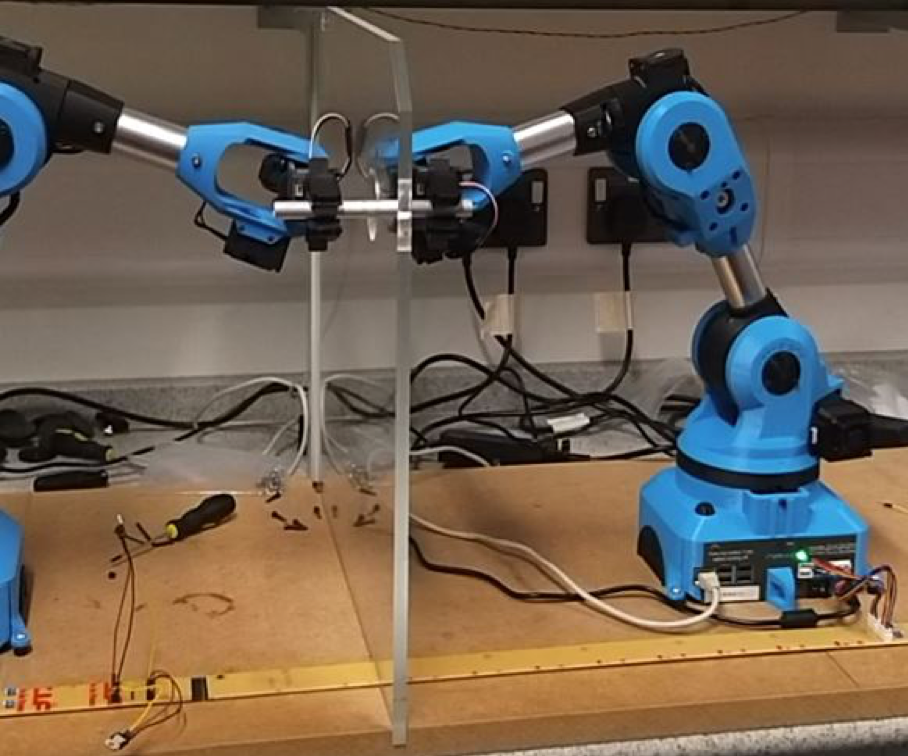

First, working in four groups of four, the students built robot arms from a kit produced by Niryo robotics. With 6 degrees of freedom and controlled via a Raspberry Pi with Linux and ROS, these kits provide an excellent introduction to the mechanical construction, control and programming of robot arms.

In our faculty, many student assessments are structured as competing groups, with each group working in isolation from others. In a one-year MSc, it’s very important to get the cohort working together early on. I wanted to devise a task where students first work in small groups to achieve a first-stage goal, and then all the groups collaborate to achieve a single, overall outcome. This kind of collaboration also models industrial practice, where collaboration between groups within a business is essential.

David Chapman, our ever helpful senior technician, built a structure allowing us to mount the robots on a secure base, separated by Perspex partitions each with a small hole. The students’ task was to program the robots to collaborate in order to pass a short metal rod from one end of the robot chain to the other, through the holes. The robots coordinated the passing of rods using electrical signalling.

Students worked through various mechanical challenges to build the kits, including faulty parts and defects in the 3D printing – a practical introduction to real robotics engineering! They learned a new graphical programming paradigm – Blockly, and for some carried out their first digital electrical systems integration.

On the day of assessment, there was a great sense of excitement in the robotics lab. I was delighted at the level of engagement and commitment shown by each and every student. They had worked effectively across groups to devise a coordination strategy between the robots, and in doing so had learned new skills in teamwork and collaboration. However, at the assessment time of 5pm, some fine tuning was still needed. At 7pm it was very nearly ready, as these things often are. The devil is in the detail of course. At 10:45pm the students finally got all the robots working together, and sent me several videos to prove it.

This exercise taught our students some specific technical skills, and has given them a wider appreciation of the challenges of practical robotics. It has also equipped them with new team working skills, and an appreciation of the skills and talents of one another. I’ll be looking for more opportunities to have students collaborate like this in future.

View the MSc Robotics and Autonomous Systems: Robot Arm Challenge video on Vimeo.