Author: Georgina Beardsmore -

The Competition

The Efficiency for Access Design Challenge (in partnership with Engineers without Borders) is a global competition that works towards accelerating clean energy access. University teams from across three continents came together to enhance the efficiency and affordability of everyday appliances.

The focus this year was to design affordable off-grid appliances for countries within the bottom 50 of the Human Development Index. It is predicted that over 500 million people in Sub-Saharan Africa will require off-grid solutions to meet the United Nations Sustainable Development Goals of universal energy access by 2030. Targets are concentrated in developing countries; small villages served by electricity generators called mini-grids and rural areas using solar modules (Solar Home Systems - SHS). Due to the associated inefficiencies, off-grid communities are limited to basic, low power devices such as lighting and mobile phone charging. To provide the means for cooking, home cooling, refrigeration and entertainment, affordable and efficient off-grid appliances are needed, to accommodate for the low energy supply.

Our Design

Our team decided to design an off-grid refrigerator as refrigerators use twice the energy of all other household appliances combined within off-grid homes, making it the most significant opportunity to improve the quality of life of many consumers and have a positive environmental impact.

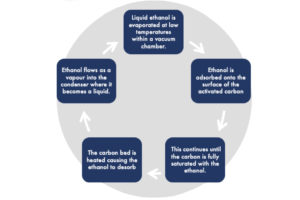

The team explored alternative refrigeration solutions such as communal refrigeration, however these were deemed unfeasible. Considering commercial and consumer needs, the cooling technology selected was carbon-ethanol cooling, a novel technology that offered an opportunity for innovation compared to conventional vapour-compression cooling. It is an environmentally friendly technology that utilises characteristics of the working pair (carbon and ethanol). This technology is capable of maintaining the required safe temperature of 3°C to 5°C within the inner cabinet of the refrigerator with 100mm of polyurethane insulation and horizontal lid opening. Activated carbon can be sustainably sourced from a variety of natural, carbonaceous sources like palm- kernel shell, coconut shell, groundnut shell and palm trunk. Ethanol is environmentally friendly, widely available and can be easily produced from natural resources. This is a significant improvement on conventional vapour-compression cooling, which requires toxic refrigerants. The technology’s ability to operate solely from a solar thermal collector increases the circuit’s efficiency in areas with higher solar radiation. The team designed the refrigerator for under $200 including materials and manufacturing costs.

Grand Finals

Throughout 2nd semester the team worked on the design of the refrigerator, including both technical design and business plan. Throughout the semester we were given feedback from industry, helping to improve our design. On the 17th June the team pitched our final design to a panel of engineers and had the opportunity to see the great work of other university students from across the world. The Grand Finals took place on the 25thof June where we won the bronze award for our design of an ethanol-carbon refrigerator.

Team members:

Jey Ashokkumaar (Project Manager), Javier Klatovsky (Business Lead), Llyr Jones (Technical Lead), Georgina Beardsmore (Design Lead), Thvinesh Pathmanathan (Cooling Engineer), Eliot Serrano-Davey (Cooling Engineer)

Respond