Author: Andy Green, Manufacturing Engineer in the Department of Mechanical Engineering

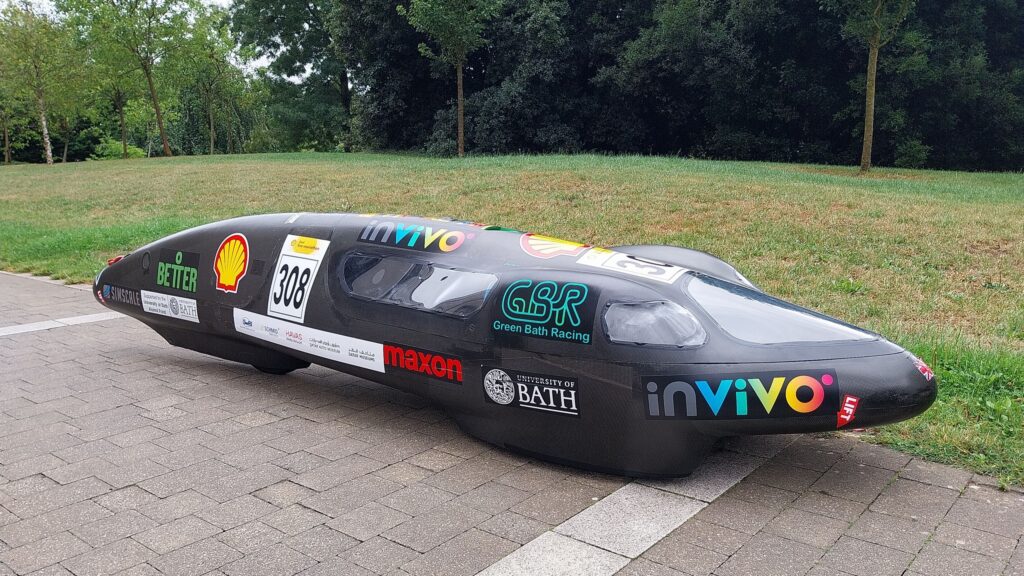

Green Bath Racing (GBR) has returned from the 2025 Shell Europe and Africa Eco-Marathon, held at the Silesia Ring in southern Poland. This was the second year that the team entered the Battery electric category. They improved from 8th overall to an impressive 4th position, achieving 828 km/kWh. The team retains the best ever UK result. The vehicle could travel 130km on the energy to boil the average 1.7-litre kettle.

Driver, Marie Ringard, drove the vehicle around a 1.3 km circuit at an average speed of 25km/hr (approx. 15 mph). The total energy for 11 laps was measured accurately using a joule meter.

The team developed their driving strategy using a simulation of the track and the vehicle dynamics to achieve the minimum average speed and to minimise energy loss. The best result of 828km/kWh was achieved on the second competitive run. Following a double check of the vehicle by the competition scrutineers, the team were excited to move into 3rd place.

On the following day, various improvements were made to the vehicle. But the weather was significantly warmer and as the track heated during the day, the vehicle's performance declined from 823, 781, to 731km/kWh. The track temperature for the last run was 55 degrees, and it became clear that the stickiness of the surface caused lower results for most teams. Frustratingly, the team lost 3rd place.

On the last day, the team had one run left and managed to get around 5th in the queue to achieve the coolest conditions. Again, it was very hot and even at 10:30, the track was already over 40 degrees. The team implemented their best vehicle improvements and adjustments to the powertrain. Sadly, the already warm track prevented the performance improvements from being realised. The 6th run achieved 825.9 km/kWh, and although lower than the team wanted, it was an excellent result. It consolidated the impressive performance of the vehicle and team.

Following the event, Team Manager, Nils Mallet and Technical Lead, Gauthier Charbon drove the vehicle the 1000-mile-plus journey back in the department van. The rest of the team flew back from Katowice to Luton airport.

All team members displayed impressive performances, carrying out their roles seamlessly. Additionally, everyone was keen to take opportunities to improve the vehicle and the driver feedback. Many ideas were implemented at the event with the use of a 3D printer and ingenuity. Other ideas have been brought home to develop in time for next year. The team is very grateful to the support from the faculty and from sponsors, without whom none of this would have been possible.

Respond